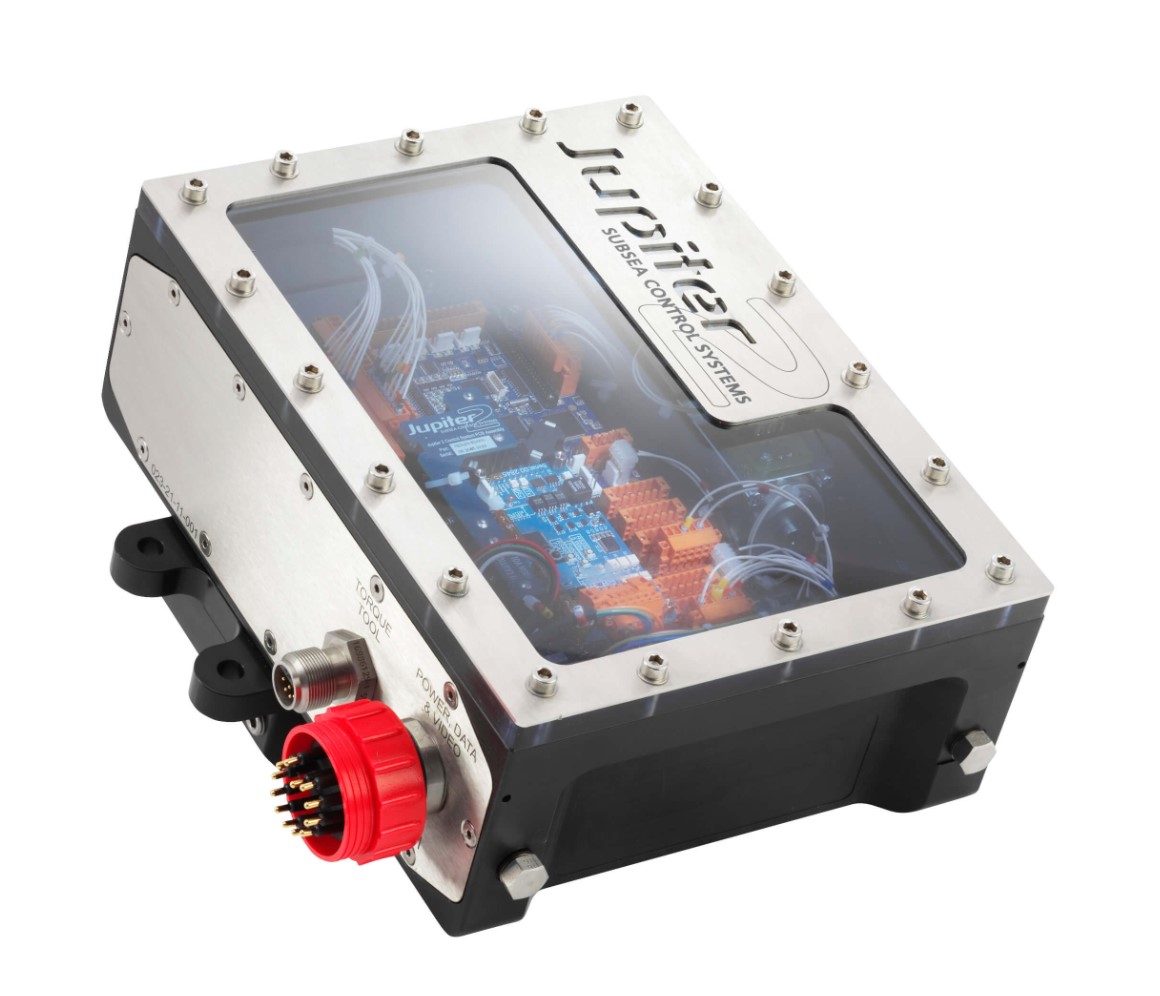

The Jupiter2 Torque Tool Control System provides precise, repeatable control of Torque Tools for high-integrity applications, featuring a single valve pack with integrated proportional control. Compact and cost-effective, it is compatible with hydraulic Torque Tools on any Work Class ROV, controlled through Jupiter GUI software on a PC or laptop, requiring only power and communication via RS232, RS485, or Ethernet. The system includes automatic calibration, user-customizable settings, comprehensive diagnostics, and optional data-logging. An Impact Drive mode allows configurable pressure, speed, and duration to apply controlled impact torque, ideal for safely freeing stuck valve stems in a reliable, repeatable manner.